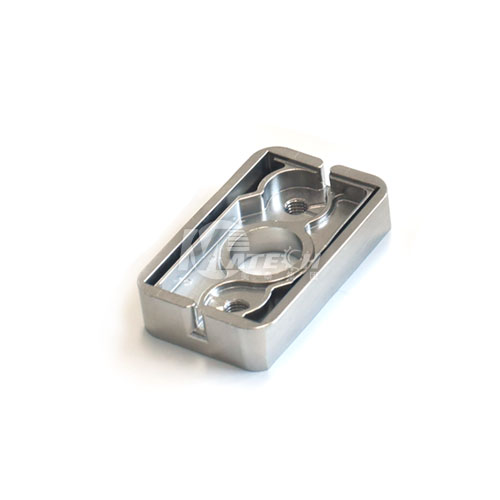

Metal powder injection molding has unique chemical composition, mechanical and physical properties, which cannot be obtained by traditional casting methods. The use of powder metallurgy technology can be directly made into porous, semi-dense or fully dense materials and products, such as oil bearing, gear, CAM, guide rod, cutting tools, etc., is a less cutting process.

Medical accessories play an important role in metal powder injection molding. Meanwhile, in the total sales of metal powder injection molding parts, medical accessories occupy a very large market.

At the same time, metal powder injection molding is also suitable for automobile industry, equipment manufacturing, metal industry, aerospace, military industry, instruments and meters, hardware tools, electronic appliances and other fields of spare parts production and research, related raw materials, auxiliary materials production, all kinds of powder preparation equipment, sintering equipment manufacturing. Products include bearings, gears, carbide tools, molds, friction products and so on. In military enterprises, heavy weapons and equipment such as armor-piercing bullets, torpedoes, aircraft and tanks and other brake pairs need to adopt POWDER metallurgy technology production. In recent years, POWDER metallurgy auto parts has become the largest market in China's POWDER metallurgy industry, and about 50% of auto parts are POWDER metallurgy parts.